Flexibility in Linear Motion: Choosing the Best Bearing

PBC linear utilizes its extensive portfolio of plain and ball bearings, carriages, and slides to complement industry needs, and set your ideas in motion. This article offers a brief insight into the groups of bearing options available, and how together they provide flexibility for OEM engineers. Simply put, we have the best bearing for every solution!

Simplicity in Linear Motion

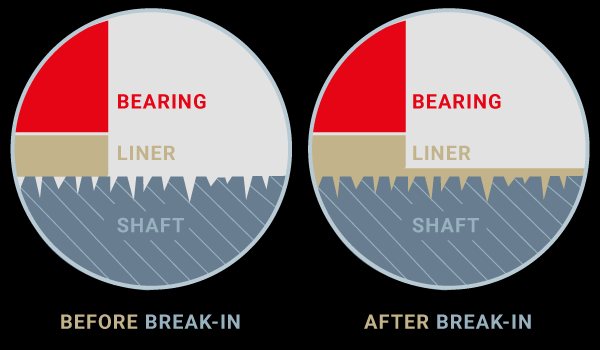

Simplicity® is precision plain bearing technology that incorporates a PTFE Frelon® liner bonded to a bearing’s outer structural shell for smooth, quiet operation. This liner, developed by PBC Linear, uses an initial break-in process between the liner and the shaft that creates a true self-lubricating bearing system. During this transfer process, Frelon deposits a microscopic film on the shaft, filling in the porosity of the shaft's surface finish, and creating a fluid running condition. Once this self-lubricating process is complete, the self-lubricating liner will help transfer loads, dissipate heat buildup throughout the bearing, and avoid damage to the shaft and resist catastrophic failure.

Simplicity plain bearing technology can be found in many PBC Linear product categories including Round Shaft plain bearings, Gliding Surface Technology, and a range of actuators and Simplicity sliders that utilize this innovative technology.

Application strengths: Simplicity bearings are resistant to many adverse environmental factors, outperforming recirculating ball bearings under these tough conditions:

- Dirty environments containing fine and heavy particulates.

- Caustic chemicals and washdown applications.

- Submerged water applications.

- Wide temperature ranges (-400°F to +400°F) (-240°C to +204°C).

- Shock and vibration (no metal-to-metal contact).

- Short stroke applications where ball bearing technology fails.

- Note: Extremely long runs can be achieved utilizing the Simplicity SRA-supported shaft and rail assemblies.

In addition, Simplicity bearings can benefit applications with heavier load capabilities, and provide easy installation and maintenance-free, long life. While they also allow for good precision, recirculating ball bearings offer the advantage of preloading to an exact specification for high stiffness and precision. Typical friction coefficients for bearing types are important to note as well. Dynamic coefficient of friction values for Simplicity plain bearings equal 0.125 , with linear ball bearings at 0.005, and 0.020 for roller bearing technologies.

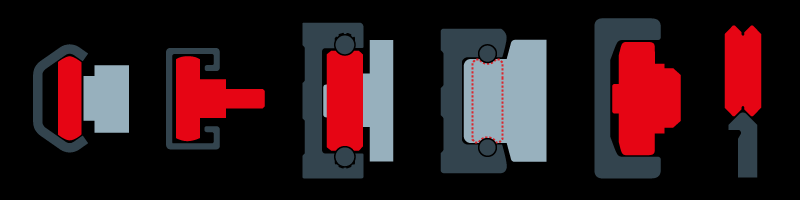

Flexibility with round shaft bearings

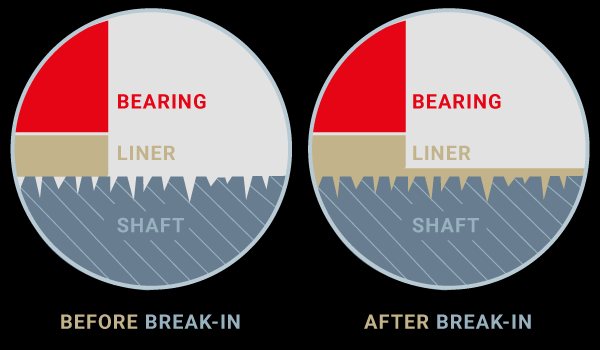

Round shaft bearings are offered in many sizes and configurations, including open, closed, and double wide. Depending on the product, they are available in Imperial, Metric, and JIS Metric sizes. This extensive product line features bearings that utilize either Frelon liners or recirculating ball tracks for their point of contact to the shaft. Options include:

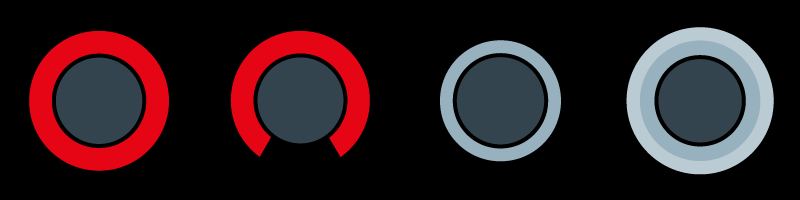

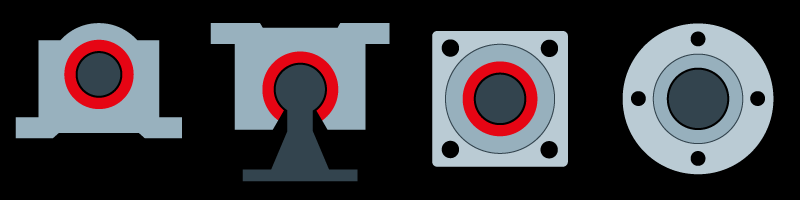

Housings with built-in round shaft bearings can incorporate either the Simplicity plain bearings or ball-type bearings listed above. The main difference is that the housing integrates flange mounting features to make installation easier, while also protecting bearings, extending their operating life, and simplifying maintenance. Options include:

Flexibility with hard working rollers and roller type carriages

Rollers and roller type carriages can be found in our cam rollers, patented Integral-V Technology™ (IVT), and with our line of roller pillow blocks. They are often used in dirtier or higher load applications with long travel requirements. Cam Roller Technology and Integral-V Technology and V-Guide products can be butt-joined end-to-end to create long runs (Please note some variation in roller preload may be noticed when transitioning among all rail sections). Each product offers its own unique design use, especially where precision is concerned. In fact, many of these products can be a more cost-effective solution in less precise applications where classic Profile Rail has historically been the first choice.

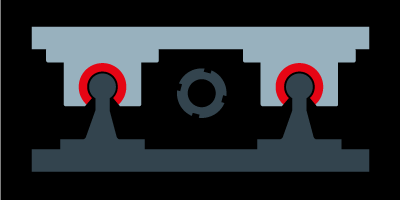

Cam roller technology represents the hard-working line of rollers and carriages that move along single linear track rails. These big haulers are listed below along with their top radial load capacities:

- Commercial Rail is your introduction to sturdy, low-cost linear motion (292 lb / 1.3 kN)

- Hardened Crown Rollers have a one-size fit for many needs (292 lb / 1.3 kN)

- Redi-Rail offers practical precision with metric, inch, and low profile versions (1,326 lb / 5.9 kN)

- Hevi-Rail is the apex weightlifter (13,264 lb / 59 kN)

- V-Guide offers a low-cost V-type wheel solution (2,226 lb / 9.9 kN per wheel)

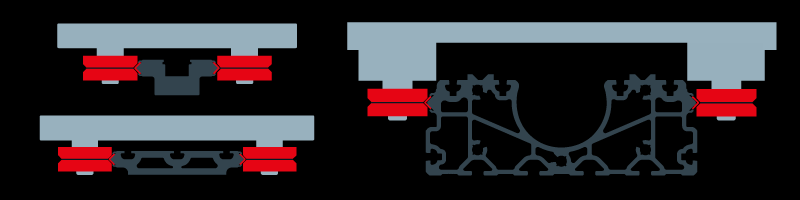

Integral-V Technology™ (IVT) uses our patented SIMO® process to create an environmentally adaptable linear guide system with multiple variations of V-type rails and rollers for high speed and rigidity. The rollers are driven across hardened stainless steel V-raceways embedded into durable anodized aluminum rails. All seven variations offer advantages over profile rail that includes fewer components for less installation time and downtime, and superior performance within harsh environments. Both IVT and V-Guide rollers and rails excel in environments where sticky liquids and/or sticky over-sprays can adhere to the rail. The V-rollers act as a squeegee that self-cleans these contaminants, sweeping them away without hindering linear motion.

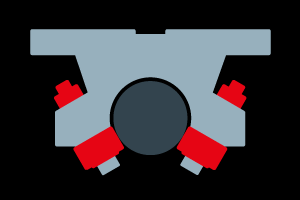

Roller pillow blocks are versatile bearings for round shaft travel. They are available in single, double, and twin roller pillow block types, and in various shaft diameters. The roller pillow block product line can accommodate misalignment in shafts, making this a great alternative to the popular profile rail technology. Other notable application strengths include:

- Loads up to 12,500 lb / 55.6 kN

- Corrosion resistance

- High speeds and long travel

- Interchangeability with industry standards

Flexibility with plain bearing systems

Gliding Surface Technology (GST) and Simplicity linear slide assemblies bring us back to our patented Simplicity liners. This group of bearing and rail systems employ our plain bearing Frelon technology and a two-piece aluminum design that’s easy to assemble, align, and maintain. Much of these systems can adopt motor driven technology for use as actuators, or have already been integrated into our actuator products such as our Uni-Guide Actuator.

PBC Linear doesn’t recommend butt joining Gliding Surface Technology rail sections end to end, but if you decide to, then we suggest using the Compensated Fit (Looser Fitting) Carriages. Also, providing gradual lead-in chamfers on the ends of all rail sections will allow the carriage to transition easily between adjacent rail sections.

- Our complete collection of Simplicity linear slide assemblies gives customers multiple configurations of manual and motorized operations, while employing all the benefits of Simplicity technology.

Discover your ideal linear motion solution:

Discover more on the strengths and applications for Simplicity plain bearing liners with

Discover more on the strengths and applications for Simplicity plain bearing liners with

Discover more on round shaft bearings and their proven applications with

Discover more on round shaft bearings and their proven applications with

Find out more information on sleeve, flange bearings and more with

Find out more information on sleeve, flange bearings and more with