Design Factors for Simplicity Bearings

When designing applications to use Simplicity® linear bearings, there are factors to consider within your application, such as size, temperature, orientation, and running clearances.

Measurement Category

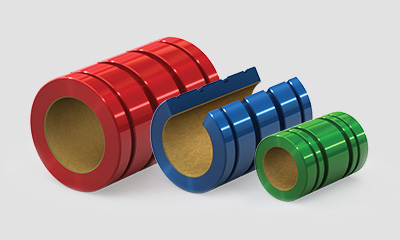

We often hear these questions when discussing our Simplicity family of linear plain bearings: “Why are there different colors? Why are there red, blue, and green bearings?” The answer is quite simple. The colors relate to three different measurement standards common in the industry. These three categories are:

Inch Series (Red)

- Designed to interchange with industry standard inch series linear bearings.

- Sizes for shafting ranging from 3/16” up to 4”.

ISO Metric Series (Blue)

- Designed to interchange with European ISO metric standard linear bearings.

- Sizes for shafting ranging from 5 mm to 80 mm.

JIS Metric Series (Green)

- Designed to interchange with Asian JIS metric standard linear bearings.

- Sizes for shafting ranging from 6 mm to 150 mm.

All of the Simplicity linear bearings come standard with the FrelonGOLD® self-lubricating liner and do NOT require external lubrication.

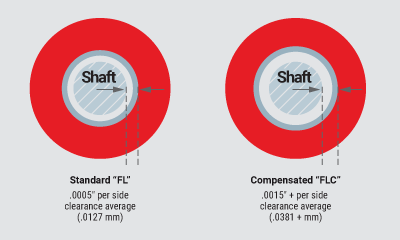

Precision vs Compensated

Within the family of Simplicity linear bearings, precision and compensated are terms that refer to the two classes of available running clearances. It is important to understand the difference in these two classes for the design and installation process to ensure that bearing systems will perform properly.

If you are building a linear slide system or replacing existing bearings, a simple way to check for the difference between a precision and a compensated bearing is to place each on a shaft. In this side-by-side comparison, you will distinctly feel more play caused by the greater clearance in the compensated bearing. Note that many parallel shaft applications will run with an “FL” (Precision) bearing on one rail and “FLC” (Compensated) bearing on the opposite rail to accommodate for slight misalignments. Below is a quick reference comparison for Simplicity bearings:

Precision:

- Use the prefix “FL” in the part number.

- Has the tightest running clearance (approximately .001” or .025mm total).

- Recommended for applications that require tighter tolerances and stiffened assemblies.

- Not recommended for parallel shaft applications where misalignment can lead to binding issues.

Compensated:

- Use the prefix “FLC” in the part number.

- All dimensions the same as precision bearings, except for more clearance in the I.D. between the shaft and bearing (approximately .003” or .07 mm total).

- Ideally suited for parallel shaft applications.

Temperature Range

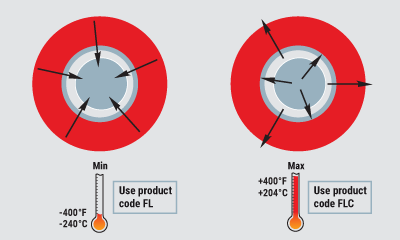

A major advantage of the self-lubricating Simplicity linear bearings is that they can be used over a very wide temperature range (−400°F / 400°F) (−240°C/+204°C). The fact that they are “self-lubricating” allows for the elimination of external grease or oil that is often the limiting factor on a bearing’s performance.

The thin bearing liner of Frelon® materials allows heat to dissipate through the bearing shell in high temperature applications. The bearing material maintains its performance characteristics while keeping thermal expansion to a minimum.

The standard bearing I.D. options are designed for use in most industrial applications. For temperatures below 0°F, the standard bearing I.D. is recommended (FL series bearings). For extreme high temperatures, the compensated I.D. bearing (FLC series) is recommended due to the increased running clearance.

CAUTION: It is always best to inspect actual size at extreme temperatures to ensure the proper running clearance.

Orientation and Inverted Loads

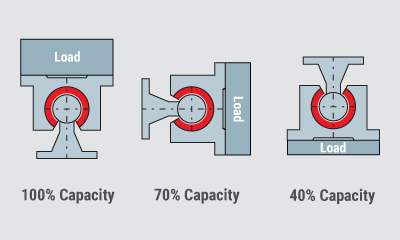

Most linear bearings can be used when turned 90° or even inverted, but there are a few factors to consider when mounting linear bearings in this orientation.

In applications where open style bearings are to be mounted at a 90° or inverted completely, plain bearings like the Simplicity® self-lubricating linear bearings have a distinct advantage over traditional linear ball bearings and grooved plastic insert bearings. Simplicity bearings are a one-piece design with a greater contact area, offering a consistent bearing surface contacting the shaft. This means that no matter what the orientation is, the bearing surface will always be in contact with the shaft. In the case of ball bearings, consideration must be given to where the raceways are oriented to ensure that they are located at an angle to handle the load. The same is true of the linear grooves in a two-piece plastic bearing.

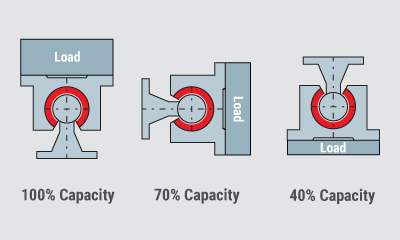

All linear bearings must be de-rated when used in a different orientation, but due to the Simplicity bearings maintaining consistent contact, they are not as susceptible to this design problem. Use the numbers in the illustration shown to de-rate the Simplicity bearings and account for the stress placed on the outer shell material of the open style bearing.