Integral-V Technology Overview

IVT provides customers with precision linear guide solutions while reducing costs

For over a decade, Integral-V™ Technology (IVT) has benefitted our customers as a reliable and cost-effective option for linear guide systems. Its unique process allows for tighter tolerances without additional cost. We designed IVT to carry heavy loads at high capacity, velocity, and acceleration while still excelling in wear resistance. These characteristics have allowed IVT to be named a Design News Golden Mousetrap finalist for Best Product category and labelled a stand-out product.

IVT Features

Integral-V provides a variety of advantages to traditional linear methods, including:

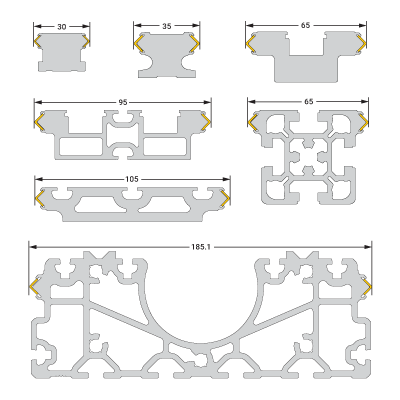

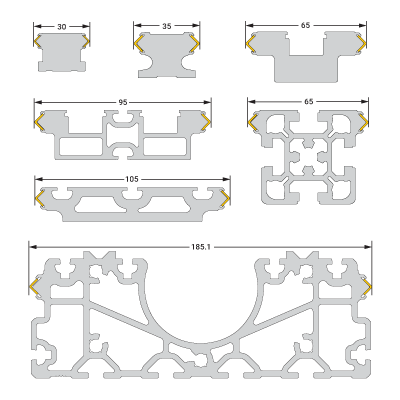

- hardened steel inserts directly embedded into aluminum structural frames, and provide tight tolerances (±0.001"/0.025mm) and unmatched linear straightness (±0.002"/ft/0.050mm). This eliminates bulky, time-consuming fasteners and tolerance stack-up, therefore significantly driving down installation time and labor costs.

- Standard carriages that utilize four V-Guide rollers, two on each side of the rail. One side is fixed, while the second side incorporates the patented side-adjustment feature.

- Maximum static load ratings ranging from 1,960 N up to 8,900 N, and an ability to handle extreme moment loads, and speed capabilities up to 12 m/s.

- precision machined rail via our proprietary SIMO® process. SIMO concurrently mills out all critical sides of the extrusion in one pass, and in the process machines out all naturally occurring inaccuracies along the rail including bow, twist, camber and warp.

- our patented side-adjustment feature. This controls preload on linear guided roller bearings mounted to a variety of carriages within Redi-Rail®, Integral-V Technology (IVT), and the SIMO Series Linear Motion Platform. This allows easy access for preload adjustment without needing to remove items mounted to the carriage.

The IVT Savings Advantage

IVT is essentially a shortcut. It allows the designer to simplify the assembly – reducing fasteners, mounting components and cost. Traditional linear guides not only require an entire menagerie of different mounting components, but they also must undergo a scrupulous aligning process. Our SIMO process eliminates inaccuracies along the rail where previously that had to be painstakingly corrected in the alignment process. Table 1, below, shows the cost comparison breakdown between traditional bearing block systems and IVT systems.

Table 1: Cost comparison breakdown

Bearing Block System

IVT System

Design Steps

Labor (min)

Labor (min)

1. Select and source components

30

10

2. Download model/drawings

5

5

4. Build and cost BOM

25

10

5. Manufacture/Procure carriage

20

20

6. Manufacture / Procure rail

20

20

7. Quality assurance

20

5

Total Time

3 hours

1.17 hours

Design cost subtotal ($60.00 per hour)

$184.80

$70.20

PBC Linear is willing to work with companies to integrate IVT into their extrusions. Our engineering team is fully prepared to adapt or modify the customer’s base design with the new Integral-V Technology to ensure a successful product.

Application Solution

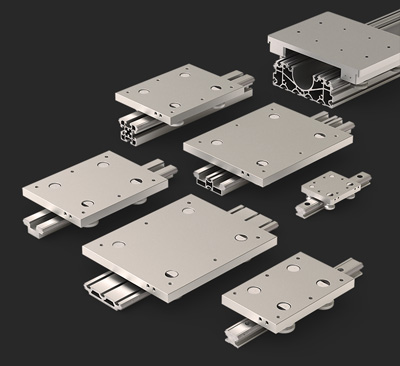

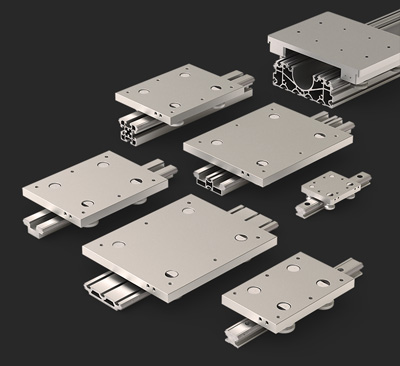

Available in multiple sizes and a range of different configurations, Integral-V is a perfect fit for the following applications:

- CNC tooling

- Sliding utility doors/tables

- Architectural mobility

- Ergonomic machine tooling

- Material transfer

Some examples of Integral-V Linear Guides applications are listed below:

- CNC Gantry — Using integrated, double bolt-on, or custom designed profiles, IVT provides sophisticated, accurate and precise positioning of CNC routers, water jet cutters, laser etching machines and machine tooling systems.

- Sliding Door/Drawer Slides — The mounting and profile versatility of IVT’s modular bolt-on configuration instantly makes it an attractive candidate for drawer slide and sliding door applications. Machine tool doors smoothly slide along the rail, even in dusty, dirty and other contaminated evnvironments.

- Patient Assist/Adjustable Tables — Patient assist tables require smooth, seamless linear positioning to ensure comfort and support. IVT linear guides are end-joinable with dowel pins for longer length applications. Their incredibly smooth/flat surfaces (±.002’’), and parallelism (±0.001’’) allow for quiet and reliable positioning and adjustments, catering to both ergonomics and patient satisfaction.

- Overhead Guidance — Usability, functionality and high load capacities like cantilevered loads are all necessary for these applications. IVT linear guide system can support an overhead TV monitor for easy-viewing access, or large tools for maneuverable work-assist applications.

More information on IVT

Find more in-depth information on IVT through the following white papers, video, and data sheet, or visit our online configurator to generate and download an exact CAD model.

White paper: Integral-V vs. Ball-bearing Linear guide rails

Senior System Design Engineer Kevin Bischel provide readers with a white paper that discusses the objective examination of both linear guide technologies based upon assembly/alignment, performance advantages, life and cost. The following are summed up in the white paper and video:

Simplifies assembly time and cost

High Rigidity/Accuracy

Large diameter rollers glide over contaminants

Precision ground rails for smooth travel

Quick system integration

Industry interchangeable

Save 40% on total installation cost

High load capacity for given envelope size

Data Sheet: Expanded IVT Linear Guide System

This newly updated and expanded version of the selection guide for the Integral-V Technology Linear Guide System is now available for download!

This selection guide focuses on the seven standard IVT rail/carriage combinations along with the addition of the high load capacity ABK series. It makes it easy for the design engineer to zero in on the best solution for any application. The IVT Linear Guide System is well suited to a wide variety of applications. These include general automation, pick-n-place applications, packaging equipment, ergonomic adjustments, medical devices, metal cutting equipment, XYZ gantry arrangements, and much, much more.

Discover your ideal linear motion solution: