Engineering Your Linear Motion Solutions

- Home

-

Product Specs

-

Linear Bearings

- Plain Linear Bearings Simplicity

- Linear Ball Bearings and Bushings

- Plain Linear Bearing Pillow Blocks

- Linear Ball Bearing Pillow Blocks

- Plain Linear Bearings Flanged

- Simplicity Bearing Flange Mounts

- Linear Ball Bearing Flange Mounts

- Die Set Plain Linear Bushings

- Linear Plain Bearing Die Set Flange Mounts

- Simplicity Precision Sleeve Linear Plain Bearings

- Square Bearings and Linear Rails

- Roller Pillow Blocks

- Linear Shafting & Supports

- Slew Ring Bearings

- Gliding Surface Linear Slides

- Integeral-V Linear Slides

- CAM Roller Linear Slides

- Lead Screw & Ball Screw Assemblies

-

Linear Actuators

- BE Integrated Ball Screw Linear Actuator Series

- BS Miniature Ball Screw Motor Series

- LSM Lead Screw Motor Series

- LN Non Captive Type Linear Actuator Series

- LC Captive Type Linear Actuator Series

- MS Linear Slide Series

- ML Miniature Linear Actuator Series

- CS Compact Series Linear Guide System

- G Uni Guide Actuator

- MR LS Min Rail Actuator

- MR MS Min Rail Actuator

- UG Series Linear Motion Platform

- PLA Linear Actuator Series

- MTB Linear Actuator Series

- MUK Linear Actuator Series

- Simplicity Linear Slide Assemblies

- Automation Solutions

- 3D Printing

- View All Products

-

Linear Bearings

-

Shop

-

Linear Bearings

- Simplicity Plain Linear Bearings

- Linear Plain Pillow Blocks

- Linear Ball Bearings

- Linear Ball Bearing Pillow Blocks

- Roller Pillow Blocks

- Precision Sleeve Linear Bearings

- Simplicity Flange Mount Plain Bearings

- Flange Mount Plain Linear Bearings

- Simplicity Die Set Flange Mounts

- Die Set Linear Bushings

- Flange Mount Linear Ball Bearings

- Square Linear Bearings and Rails

- Linear Shafting & Supports

- Slew Ring Bearings

- Gliding Surface Linear Guides

- Integral-V Linear Guides

- Cam Roller Linear Guides

- Lead Screws & Ball Screws

- Linear Actuators

- 3D Printing Parts

-

Linear Bearings

- Tools

- Resources

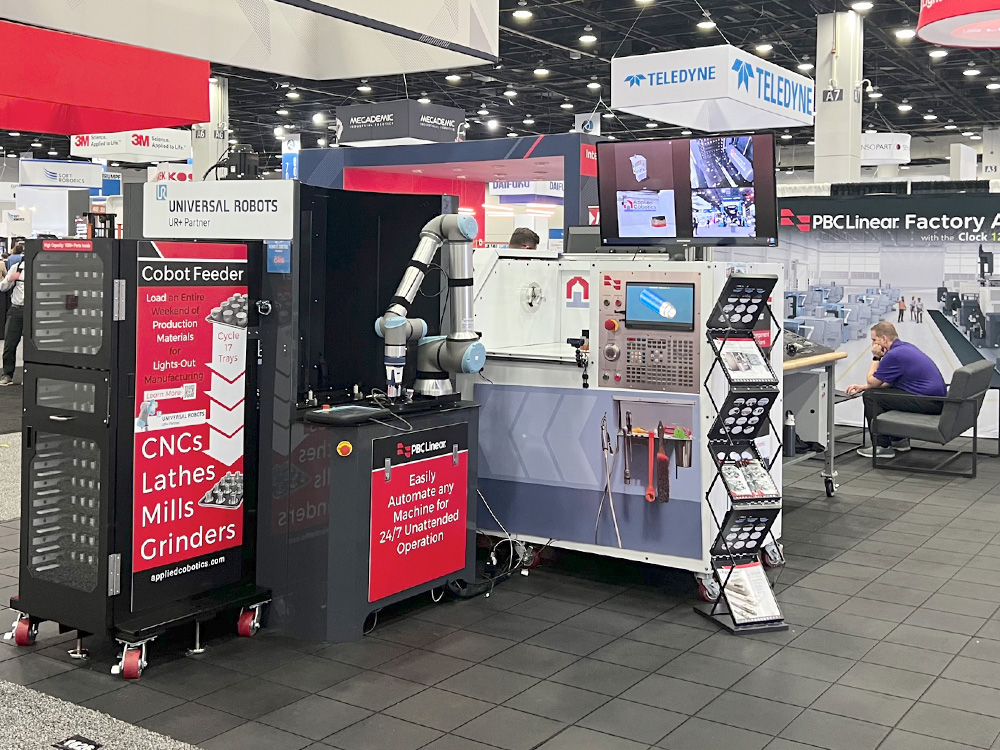

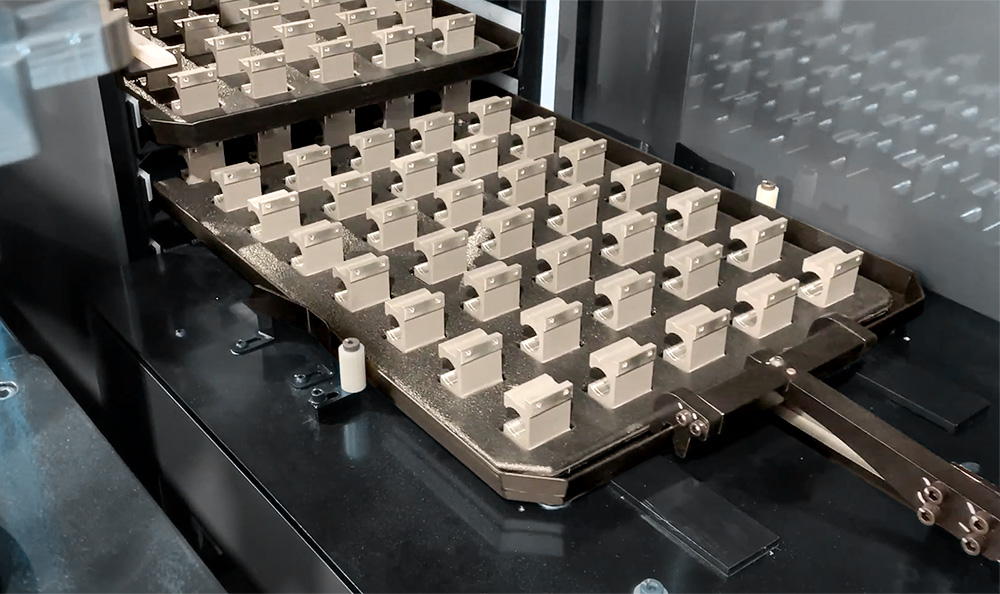

- Events

- About

- Connect with Us

- Request A Quote