Engineering Your Linear Motion Solutions

- Home

-

Product Specs

-

Linear Bearings

- Plain Linear Bearings Simplicity

- Linear Ball Bearings and Bushings

- Plain Linear Bearing Pillow Blocks

- Linear Ball Bearing Pillow Blocks

- Plain Linear Bearings Flanged

- Simplicity Bearing Flange Mounts

- Linear Ball Bearing Flange Mounts

- Die Set Plain Linear Bushings

- Linear Plain Bearing Die Set Flange Mounts

- Simplicity Precision Sleeve Linear Plain Bearings

- Square Bearings and Linear Rails

- Roller Pillow Blocks

- Linear Shafting & Supports

- Slew Ring Bearings

- Gliding Surface Linear Slides

- Integeral-V Linear Slides

- CAM Roller Linear Slides

- Lead Screw & Ball Screw Assemblies

-

Linear Actuators

- BE Integrated Ball Screw Linear Actuator Series

- BS Miniature Ball Screw Motor Series

- LSM Lead Screw Motor Series

- LN Non Captive Type Linear Actuator Series

- LC Captive Type Linear Actuator Series

- MS Linear Slide Series

- ML Miniature Linear Actuator Series

- CS Compact Series Linear Guide System

- G Uni Guide Actuator

- MR LS Min Rail Actuator

- MR MS Min Rail Actuator

- UG Series Linear Motion Platform

- PLA Linear Actuator Series

- MTB Linear Actuator Series

- MUK Linear Actuator Series

- Simplicity Linear Slide Assemblies

- Automation Solutions

- 3D Printing

- View All Products

-

Linear Bearings

-

Shop

-

Linear Bearings

- Simplicity Plain Linear Bearings

- Linear Plain Pillow Blocks

- Linear Ball Bearings

- Linear Ball Bearing Pillow Blocks

- Roller Pillow Blocks

- Precision Sleeve Linear Bearings

- Simplicity Flange Mount Plain Bearings

- Flange Mount Plain Linear Bearings

- Simplicity Die Set Flange Mounts

- Die Set Linear Bushings

- Flange Mount Linear Ball Bearings

- Square Linear Bearings and Rails

- Linear Shafting & Supports

- Slew Ring Bearings

- Gliding Surface Linear Guides

- Integral-V Linear Guides

- Cam Roller Linear Guides

- Lead Screws & Ball Screws

- Linear Actuators

- 3D Printing Parts

-

Linear Bearings

- Tools

- Resources

- Events

- About

- Connect with Us

- Request A Quote

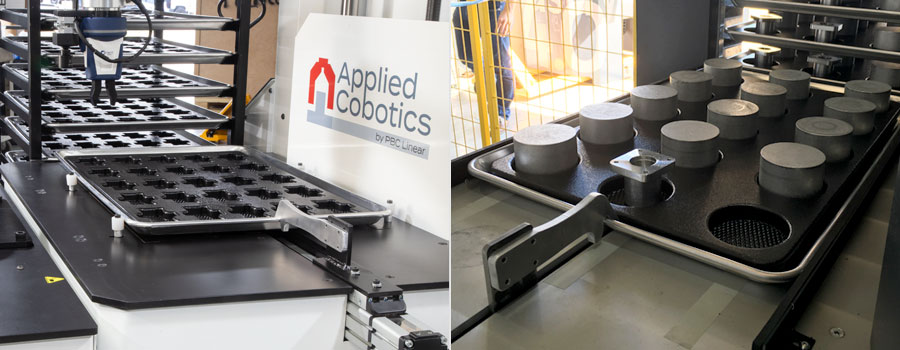

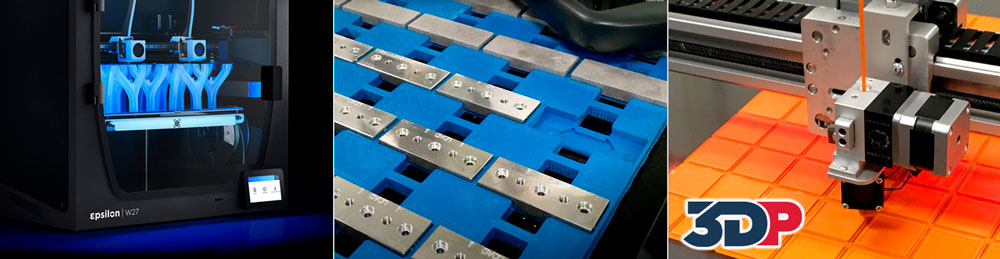

There's a stigma right now that cobots and their accessories take a lot more money to install and get up and running. The truth is quite the opposite, as our team has consistently found that the full return on investment (ROI) can be realized within that first year, resulting in substantial long-term gains. Applied Cobotics can then help you get started or advance what you have already begun with its cobot packages and related tools involving gripper options, 3D printers, and dunnage parts-tray creation.

There's a stigma right now that cobots and their accessories take a lot more money to install and get up and running. The truth is quite the opposite, as our team has consistently found that the full return on investment (ROI) can be realized within that first year, resulting in substantial long-term gains. Applied Cobotics can then help you get started or advance what you have already begun with its cobot packages and related tools involving gripper options, 3D printers, and dunnage parts-tray creation.