Delicate, critically important biological samples are carefully transported at high speeds using a complete linear motion gantry solution designed by PBC Linear. A medical equipment manufacturer needed a solution for quiet, fast-paced pick-and place automation on their newly designed sample transporting system. Speed and care were crucial for maintaining efficient productivity; however, PBC Linear was met with the challenge of balancing the two.

The medical equipment design company relies on the speed of their automated laboratory products to promote high efficiency and performance. Safely storing and transferring samples in the fastest way possible is the bottom line. For a competitive design in this market, the design company turned to PBC Linear for a complete solution.

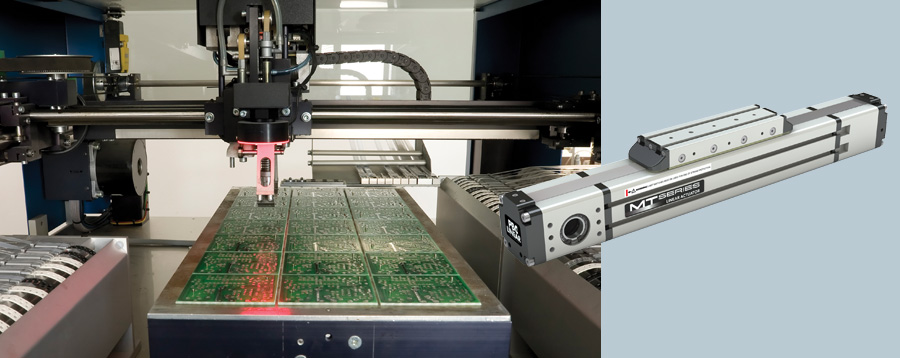

Using three high performance MTB actuators assembled into an XYZ gantry, the new sample transfer system supported a wide working envelope. PBC Linear MTB series actuators are driven by steel reinforced timing belt, which ensures high acceleration and fast travel. MTB series are composed of an anodized aluminum housing and carriage; which gives the system strength while remaining lightweight and corrosion resistant. Easily mountable and installed in multi-axial Cartesian gantries, the MTB series provided the fast, precise and repeatable guidance necessary for the sample transferring operation.

For careful handling of the samples, PBC Linear installed their ML series mini-actuator to perform the gripping operation. Compact, lightweight and precise, the ML series mini-actuator provides precise linear motion in tight spaces. In this application, the ML moved the gripper in and out of place with careful, sophisticated control.

PBC Linear’s complete design was a perfect combination of speed, precision and control—swiftly transporting samples to their desired locations without loss of product or time.